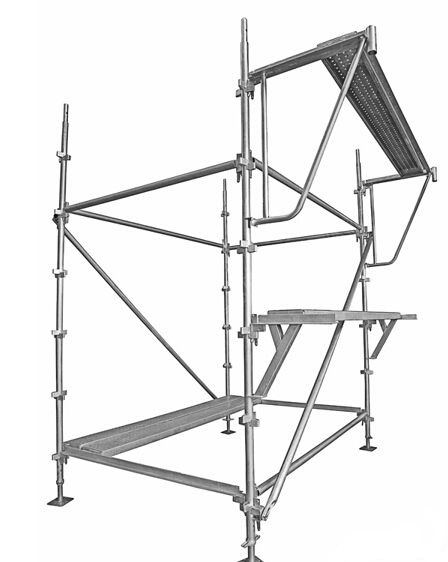

The description of kwikstage of scaffolding:

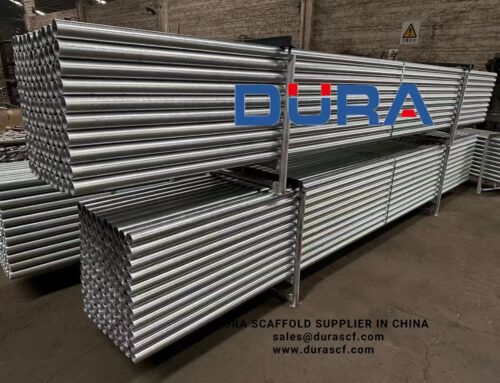

Kwikstage scaffolding consists of components such as standards, diagonals, ledgers, transoms, brackets and braces. It is easy and quick to disassembly and assembly for staff, which is good for labor and time saving. Kwikstage is a very stable and reliable structure that is widely used in the construction of houses, bridges, tunnels, water towers and other residential or commercial buildings. The main components areφ48X3.25, Q235 production standards. The surface treatment is processed by hot dip galvanized, or painted, fully integrated with weld pipes. The service life is estimated more than 15 years due to the strong anti-corrosion ability and multi-functional.They are mainly used in Australia, New Zealand, Fiji and other South Africa countries. The disadvantage of this scaffolding is that the ledgers and transoms should be welded connectors on it, so that it will cause on higher labour cost and more use of raw materials.

How to erect the kwikstage scaffolding? Here is the process of kwikstage scaffolding installation

- Before the scaffold erection and dismantling, the engineering technical department should prepare the installation and dismantling plan.

- Firstly, they need to level the standards and ledgers.

- Before starting to erect the standard, they need to variate in the platform height first, prepare the ledger and put it in place and extend it, then erect the standard.

- When erecting the standard, it is best to cooperate with two people.one people support the standard, put one head on the base, and the other person use the foot to hold the bottom of the standard, and help to erect the standard until the standard is erected. After straight, insert it into the base.

- After completing the above steps, the staff start to install the transoms and assemble the return transoms.

- The height of one erection should not exceed two steps above the adjacent connecting wall. After each step of scaffolding, the step distance, vertical distance, horizontal distance and vertical of the pole should be corrected.

- Both the base and the backing plate should be accurately placed on the positioning line; the backing plate should be a wooden backing plate with a length of not less than 2 spans and a thickness of not less than 50mm, or channel steel.

- The last two step are assembling planks and adding braces.

Leave A Comment