Ringlock scaffolding installation

Ringlock scaffolding was introduced from Europe in the 1980s, and is an upgrade from cuplock scaffolding. In the begining, it was founded by LAYHER, and it is also called layer frame. Moreover, ringlock scaffolding is a kind of socket scaffolding, its connection method, erection method is more simple, convenient, more efficient than the traditional scaffolding, so it is one of the most popular scaffolding type these days. Other than that, ringlock scaffolding system is used in a wide range of applications, including bridge projects such as viaducts, tunnel projects, factories, elevated water towers, power plants, oil refineries, etc. It can be used in small projects like bleachers, viewing stands, modeling frames, stair systems, party stage set-ups and sports stands,etc. Therefore, with these background introduction, how is the bearing capacity and erection order of the ringlock scaffolding? Let’s take a deeper understanding of the following.

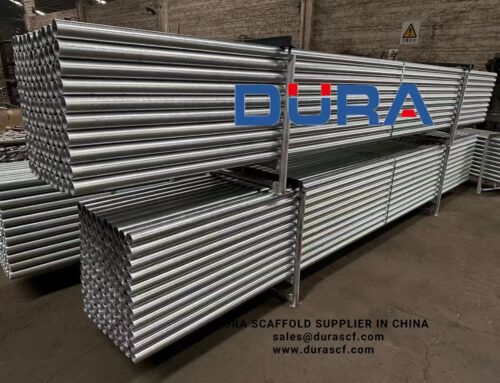

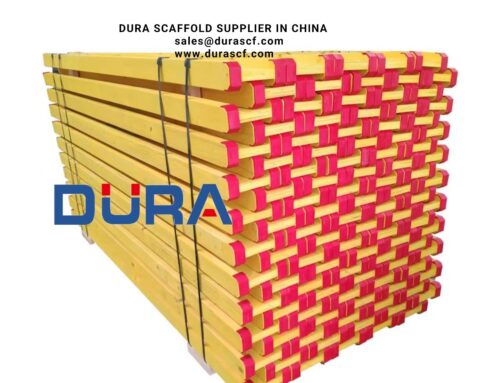

First of all, when using Ringlock scaffolding to erect double-row scaffolding, the specification requires that the height of the erection should not be higher than 24m. A ringlock scaffolding system composed of standards, ledgers, base collar, diagonal braces, steel plank, screw jack, bracket, toe-board and staircases, which are the basic units of ringlock scaffolding. Furthermore, there are also Heavy Truss, Intermediate Transom and Strengthened U ledger as the additional components for specific needs.

In the step of building ringlock scaffolding, first arrange the adjustable screw jack to a fixed point, and then place the main frame sleeve part of the base collar upward over the adjustable base, and the lower edge of the base collar should be completely placed in the groove of the wrench force plane. After that, put the ledger end into the small hole of the round ring so that the front of the ledger against the standard’s pipe, and then use the wedge-shaped pin through the small hole to knock tightly fixed. Then, stand the standard up in order and put it into the sleeve. At this step, check the position of the holes to see if the standards are inserted into the bottom of the sleeve. After the standrads are installed, put all the diagonal braces together in clockwise or counterclockwise direction. Then,put the diagonal braces into the big hole of the round ring, make the front end of the diagonal rod head against the main frame pipe, and then use the diagonal pin through the big hole and knock it tightly. Due to the steel plank use on the ringlock scaffolding normally have a O type hook, which can easily snap on the ledgers. To assemble the bracket, you need to tap the pin into the hole of the round pin, and then snap the other end onto the tube of the standard.Heavy Truss, another name is Guard Rail, to install a heavy truss, its pretty much like how to install a ledger, connect the two ends of the Heavy Truss to the round ring, and use a hammer to tighten the pins.

The ringlock scaffolding have the advantages of technically mature, solid connection, stable structure, safe and reliable capacity. The main materials are all made of low alloy structural steel (National Standard Q345B), which is 1.5 – 2 times stronger than the traditional carbon steel pipe (National Standard Q235) of scaffolding. The main components are all made of internal and external hot-dipped galvanized with anti-corrosion function, which not only improves the service life of the product, but also provides further guarantee for safety, and at the same time, it is good looking for the surface and overall structure. The product starts from the material, and the whole product processing goes through 20 to processes, each process is carried out by professional machines to reduce the intervention of human factors, especially for the production of standards and ledgers, fully automatic welding special machines are used to achieve high precision, interchangeability, stable and reliable quality. Another advantage is less structure, it is easy to build and dismantle, basic structure and special parts can make the system can be adapted to a variety of structural buildings; There are only standards, ledgers and diagonal braces three types of components for the main frame that can prevent the trouble like the lose of traditional scaffolding parts and easy to damage, in order to reduce the economic loss of the construction unit; without any movable locking parts, the maximum to prevent the traditional scaffolding movable locking parts caused by unsafe potential danger.

Leave A Comment